How Media Blasting Works for Aircraft, Auto, & Marine Restorations

Restoration projects are intricate endeavors requiring precision, expertise, and the right tools. Among these tools, media blasting stands out as a versatile and highly effective method for restoring aircraft, automobiles, and marine vessels.

In this blog post, the media blasting experts at Clean ‘N Seal explain the significance of media blasting in these restoration projects, highlighting the process, its benefits, and its applications across different industries.

The Process: How Media Blasting Works

Media blasting, also known as abrasive blasting or sandblasting, is a surface preparation technique that involves using high-pressure compressed air to propel abrasive materials onto a surface.

The abrasives used can vary in size, shape, and material depending on the specific project requirements and the type of surface being treated.

The primary purpose of media blasting is to remove paint, rust, corrosion, dirt, and other contaminants from a surface without damaging it.

This makes it an ideal method for restoring various types of vehicles and vessels that have been exposed to harsh environmental conditions or simply require a fresh start, especially those made with metals, fiberglass, and gel coats.

Types of Media Used

The type of media chosen for a blasting project depends on the material of the surface being treated and the desired outcome.

Common media types include:

- Glass Beads: Ideal for delicate surfaces, offering a gentle abrasion.

- Aluminum Oxide: Stronger and sharper, suited for tough materials and heavy corrosion removal.

- Crushed Glass: Effective for aggressive cleaning without damaging the substrate.

- Plastic Media: Great for soft metals and fiberglass, minimizing damage while removing coatings.

- Sodium Bicarbonate (Baking Soda): Non-destructive and excellent for removing tough contaminants without damaging the surface. Baking soda is also preferred when dealing with fire damage and is used for soot removal due to its deodorizing capabilities.

Effects on Different Materials

Different types of media have varying effects on materials:

- Metals: Media blasting can remove rust and old paint from metals, preparing them for a new coat.

- Fiberglass/Gel Coats: Media blasting gently removes old layers without damaging the underlying material.

- Composites: Specialized media can be used to clean and prep composite materials without causing harm.

Media Blasting in Automotive Restoration

Media blasting is most notably a highly effective technique used in automotive restoration to rejuvenate classic cars. By employing abrasive materials like aluminum oxide, this method efficiently strips away rust, old paint, and surface imperfections, revealing the vehicle's original metalwork.

The treatment is also used for truck beds and trailers that have seen too much wear and tear and need to be revitalized for more years of hauling cargo.

Benefits for Auto Restoration

- Efficiency: Media blasting quickly removes rust and paint, dramatically reducing the time needed compared to manual methods.

- Precision: The technique allows for targeted treatment, ensuring that only specific areas are addressed without harming adjacent parts.

- Surface Preparation: It prepares surfaces perfectly for subsequent processes such as welding, priming, and painting, ensuring a smooth and durable finish.

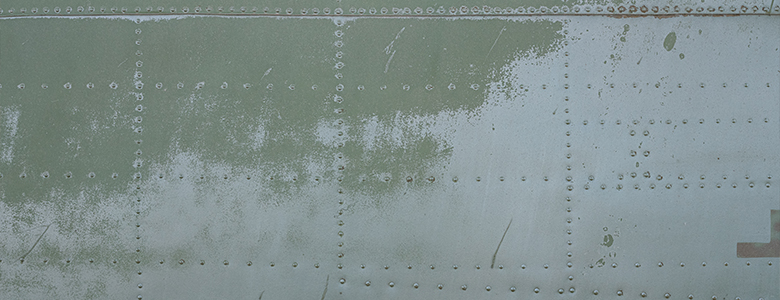

Media Blasting in Aircraft Restoration

With its unique ability to be both powerful yet gentle, media blasting plays a major role in vintage and modern aircraft cleaning and restoration.

By simply changing the abrasive media, nozzle, and pressure, a professional media blasting technician can handle all types of aircraft surface materials.

Role in Vintage Aircraft Restoration

Restoring vintage aircraft involves meticulous attention to detail, especially given the historical value of these machines.

Media blasting plays a crucial role in:

- Removing Corrosion: Aircraft exposed to the elements are prone to corrosion. Media blasting efficiently cleans the surface, preventing further damage.

- Paint Stripping: Old layers of paint are removed to reveal the original structure, essential for both aesthetic and structural restoration.

- Component Cleaning: Delicate components, such as engine parts, can be cleaned without damage using specialized media blasting techniques.

Maintaining Modern Planes

For modern aircraft, media blasting is used for regular maintenance, helping to:

- Ensure Safety: By removing contaminants and corrosion, media blasting contributes to the overall safety of the aircraft.

- Prolong Lifespan: Clean and well-maintained surfaces reduce wear and tear, extending the aircraft's operational life.

Media Blasting in Marine Restoration

Whether restoring historic wooden boats, like the Minnehaha Steamboat, or preparing modern vessels with fiberglass, metal, or composite hulls for repainting, media blasting offers an efficient and precise solution.

Especially when performed by professionals, the blasting method makes light work of an otherwise back-breaking task.

Revitalizing Boat Hulls & Decks

Boats are constantly exposed to harsh marine environments, leading to the buildup of barnacles, algae, and corrosion.

Media blasting is an effective solution for:

- Hull Cleaning: Removes marine growth and old antifouling paint, restoring the hull to a clean state.

- Deck Restoration: Cleans and prepares decks for new coatings, improving both aesthetics and functionality.

Other Marine Components

Other parts of marine vessels, such as propellers, rudders, and rails, benefit from media blasting by ensuring they are free from rust and contaminants and ready for re-coating or repairs.

The Benefits & Challenges

Like with so many other things, every benefit does come with a challenge. However, our media blasting team has the expertise and training to make the benefits far outweigh any challenges you may encounter in your restoration project.

Challenges of Media Blasting

- Media Selection: Choosing the right media for the specific material is critical to avoid damage. Working with a team of professionals experienced in media blasting will help you correctly select the best media for your specific project.

- Safety Measures: Proper protective gear and safety protocols are essential to protect operators from airborne particles. Our pros come fully equipped with all necessary PPE.

- Cost: While cost-effective in the long run, initial setup and media costs can be significant. Knowing that our experts performed the service at a fair price that brings you long-lasting results eases the cost component.

Benefits of Media Blasting

- Versatility: Can be applied to various materials and surfaces, making it suitable for diverse restoration projects, from automotive and industrial equipment to concrete restoration and even wood deck refinishing.

- Efficiency: Speeds up the cleaning and preparation process, saving valuable time.

- Effectiveness: Thoroughly removes contaminants, ensuring surfaces are pristinely clean for restoration work.

Clean ‘N Seal: Your Media Blasting Experts in Minnesota

Media blasting is a powerful technique that plays a pivotal role in the restoration of aircraft, automobiles, and marine vessels. Its ability to efficiently clean and prepare surfaces, coupled with its versatility across different materials, makes it an invaluable tool for restoration professionals, homeowners, and owners of impressive vehicles and vessels.

Reach out to our experts to learn more about how our media blasting techniques can turn a cumbersome task into a fast-paced and fun restoration project. Plus, you’ll enjoy every minute you’re driving, flying, or boating even more once your souped-up investment is back in action!